Inserts For Aluminum Turning . — how to choose the right tool for your aluminum milling application. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Whatever your component or requirements for surface finish, find highly. turning inserts and grades for non ferrous materials. Understanding the material properties and. Choose the right indexable insert for aluminum machining: — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut.

from news.thomasnet.com

Understanding the material properties and. — how to choose the right tool for your aluminum milling application. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. turning inserts and grades for non ferrous materials. with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and.

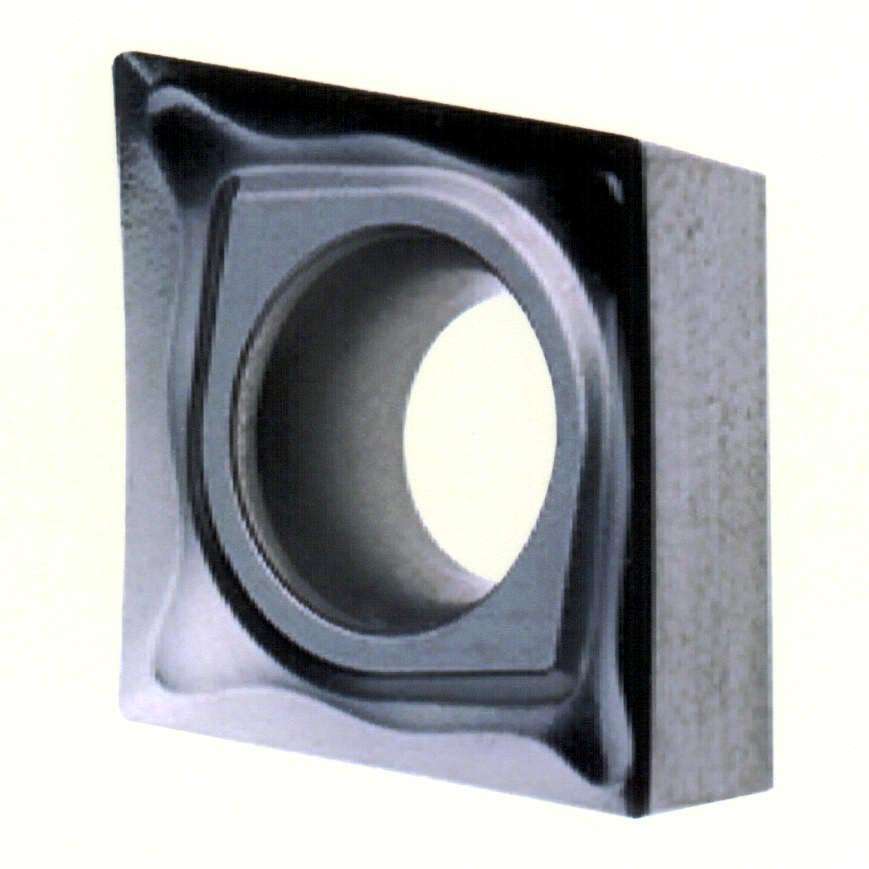

Carboloy Introduces New Grade Inserts for Turning Aluminum

Inserts For Aluminum Turning turning inserts and grades for non ferrous materials. with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. — how to choose the right tool for your aluminum milling application. Choose the right indexable insert for aluminum machining: turning inserts and grades for non ferrous materials. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Whatever your component or requirements for surface finish, find highly. Understanding the material properties and.

From www.cnccarbideinserts.com

TCGT16T304AL Aluminum Turning Inserts With Precision Grinding Large Inserts For Aluminum Turning turning inserts and grades for non ferrous materials. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles. Inserts For Aluminum Turning.

From cutoutil.en.made-in-china.com

Dcmt0702 PCBN Carbide Inserts for Turning Tools Working for Aluminum Inserts For Aluminum Turning Whatever your component or requirements for surface finish, find highly. — how to choose the right tool for your aluminum milling application. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the right indexable insert for aluminum machining: Understanding the material properties and.. Inserts For Aluminum Turning.

From news.thomasnet.com

Carboloy Introduces New Grade Inserts for Turning Aluminum Inserts For Aluminum Turning Whatever your component or requirements for surface finish, find highly. with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Understanding the material properties and. Choose the right indexable insert for aluminum machining: — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge. Inserts For Aluminum Turning.

From www.shop-apt.co.uk

VCGT 220530 ALC AK10 Carbide Inserts for Turning Ground and Polished Inserts For Aluminum Turning turning inserts and grades for non ferrous materials. Choose the right indexable insert for aluminum machining: Whatever your component or requirements for surface finish, find highly. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles. Inserts For Aluminum Turning.

From www.shop-apt.co.uk

Turning Set 72° 30' 16x16 Shank with 10 VCGT 110304 Inserts for Inserts For Aluminum Turning with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. — how to choose the right tool for your aluminum milling application. Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining: Learn what insert geometry, chip breaker and rake angles. Inserts For Aluminum Turning.

From www.shop-apt.co.uk

VCGT 160404 ALC AK10 Carbide Inserts for Turning Ground and Polished Inserts For Aluminum Turning with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Whatever your component or requirements for surface finish, find highly. — how to choose the right tool for your aluminum milling application. Understanding the material properties and. Learn what insert geometry, chip breaker and rake angles are recommended for. Inserts For Aluminum Turning.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Inserts For Aluminum Turning with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Whatever your component or requirements for surface finish, find highly. turning inserts and grades for non ferrous materials. Choose the right indexable insert for aluminum machining: — selecting the right turning inserts involves considering multiple factors, including insert. Inserts For Aluminum Turning.

From solutions.travers.com

Choosing The Right Insert For Aluminum Machining Inserts For Aluminum Turning turning inserts and grades for non ferrous materials. Choose the right indexable insert for aluminum machining: Understanding the material properties and. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Whatever your component or requirements for surface finish, find highly. with kennametal inserts,. Inserts For Aluminum Turning.

From www.carbideend-mills.com

VCGT160404 Carbide Turning Inserts , High Finish Aluminum Turning Inserts Inserts For Aluminum Turning — how to choose the right tool for your aluminum milling application. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Choose the right indexable insert for aluminum machining: with kennametal inserts, you have access to the correct performance inserts for milling and. Inserts For Aluminum Turning.

From www.aliexpress.com

2PCS VBGT160404 CBN CNC lathe turning boring insert for aluminum Inserts For Aluminum Turning Understanding the material properties and. with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Choose the right indexable insert for aluminum machining: — how to choose the right tool for your aluminum milling application.. Inserts For Aluminum Turning.

From www.aliexpress.com

VCGT160408 AK H01 Aluminum turning tools VCGT 160408 Carbide inserts Inserts For Aluminum Turning with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining: — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth. Inserts For Aluminum Turning.

From www.indiamart.com

Aluminum Insert, For Metal Turning, Size 4 at Rs 276/piece in Inserts For Aluminum Turning — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. — how to choose the right tool for your aluminum milling application. turning inserts and grades for non ferrous materials.. Inserts For Aluminum Turning.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine Inserts For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and. Whatever your component or requirements for surface finish, find highly. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. turning inserts and grades for non. Inserts For Aluminum Turning.

From obtcarbide.en.made-in-china.com

Turning Insert Tungsten Carbide Cutting Insert Ccgt/Ccgt060204 for Inserts For Aluminum Turning Choose the right indexable insert for aluminum machining: Understanding the material properties and. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. — how to choose the right tool for your aluminum milling application. with kennametal inserts, you have access to the correct. Inserts For Aluminum Turning.

From www.alibaba.com

Ccmt 060201 Pcd Turning Inserts For Aluminum Material Cutting Buy Inserts For Aluminum Turning with kennametal inserts, you have access to the correct performance inserts for milling and cutting, including both positive and. Whatever your component or requirements for surface finish, find highly. Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. Understanding the material properties and. Choose the right indexable insert for aluminum machining: — how. Inserts For Aluminum Turning.

From www.cnccarbideinserts.com

APGT1604PDER Aluminum Turning Inserts With Large Front Angle Sharp Edge Inserts For Aluminum Turning Learn what insert geometry, chip breaker and rake angles are recommended for machining aluminum. turning inserts and grades for non ferrous materials. Understanding the material properties and. — how to choose the right tool for your aluminum milling application. Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining: . Inserts For Aluminum Turning.

From www.cnccarbide-inserts.com

CCGT120404AK CCGT Insert , Aluminum Turning Inserts For External Inserts For Aluminum Turning Understanding the material properties and. — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. — how to choose the right tool for your aluminum milling application. Whatever your component or requirements for surface finish, find highly. Choose the right indexable insert for aluminum machining:. Inserts For Aluminum Turning.

From www.cnccarbideinserts.com

APGT1604PDER Aluminum Turning Inserts With Large Front Angle Sharp Edge Inserts For Aluminum Turning Choose the right indexable insert for aluminum machining: — selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. turning inserts and grades for non ferrous materials. Understanding the material properties and. — how to choose the right tool for your aluminum milling application. Whatever. Inserts For Aluminum Turning.